2012 Documentary about Coal Diggers and "The Billy Marks"

Music video "The Hard Coal Navy"

The Hard Coal Navy of the Susquehanna River

By Van Wagner

July 2010 Revised July 2012

Northeast Pennsylvania has the largest deposit of anthracite, or hard coal, in the world. For 200 years this coal has been mined and brought to the surface. On the surface, a significant amount of this coal was washed into the Susquehanna and Delaware watersheds either by heavy rains or from the era when coal was washed with stream water to remove dust. In at least one location, coal was actually transported from mine to breaker by a creek. No boat or barge but simply dumped in a creek, near Mauch Chunk, and washed several miles downstream where it was captured and processed at a breaker. For most of the 1800’s there was no market for smaller coal (pea and rice) and was considered waste. Much of this “waste” was dumped directly into the river. This makes the Susquehanna and Delaware Rivers unique. They are the only 2 rivers in North America with large amounts of anthracite coal.

Bituminous coal, or soft coal, is found throughout the Western and Northern section of Pennsylvania. However, when bituminous coal is washed into creeks and river it is crushed to dust by rolling on the bottom and rendered useless. Anthracite is hard enough that it maintains its structure and deposits in large piles in the river where the current is slow; behind bridge piers, behind islands, at the end of shallow areas, and behind bends in the river. Shale, sandstone and gravel have densities ranging from about 1500 - 2000 kg / cubic meter. Anthracite has a density of about 1100 kg / cubic meter. Anthracite’s lower density causes it to deposit together in piles on the river bottom separate from other rocks.

Beginning in the early 1900’s a market began growing for smaller coal. Electrical generation plants used the finer coal in their boilers. Men began building machines on barges that could harvest this river coal. While some dredging is recorded on the Schuylkill and Lehigh Rivers (which drain into the Delaware River), it was the Susquehanna that hosted the bulk of the Hard Coal Navy. In 1919 and 1920 over 2,000,000 tons of river coal was harvested each year.1 Harrisburg dredgers alone were harvesting 400,000 tons a year in that era and 750,000 tons were harvested on Shamokin creek. 1 There was a spike in demand for river coal during the years of World War I as the nations need for fuel was increased for the war effort.3

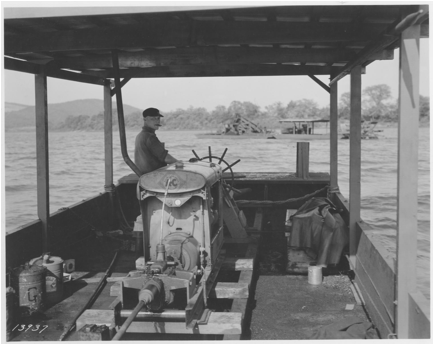

Large boats called “diggers” pulled draglines on the river bottom.6 The dredging barge was always called the digger as the old timers always “dug” coal not dredged coal.4

The digger would load flat boats or barges using powerful pumps. Once full, a boat called the “pusher” would push the loaded barge to shore.4 The pusher was powered by a paddle wheel driven by a combustion engine. Barges held about 12 – 18 tons and could be filled as quickly as 40 minutes.3 Barges were about 20 ft by 60 ft.4 At shore a “loader” was used to transfer the coal to shore by conveyor.4 From there it would be sent to a processing plant where stones and other foreign material was removed.6 The coal was then sized and ready for sale. In 1913 a dredge boat and engine could be purchased for about $200.5

An article in The Morning Press on February 22, 1938 (Bloomsburg) offers some local information worth presenting. “The dredgers take to the water in the spring, the latter part of March or early in May. If the waters have been particularly high the coal is carried further down stream and is not profitable for local dredges. On the other hand if the water is too low the boats cannot navigate advantageously and in all probability large quantities have not been carried southward. Certain rights and privileges are honored among all dredgers. In the spring the proprietor lays out his plans for the season and when a bed is found a buoy is placed at the head of the coal. Other dredgers recognize this and look elsewhere for beds. The endless bucket-line tube of the coal dredger is rapidly being replaced by the more efficient centrifugal pumps, with a six-inch intake and discharge.

The coal is pumped from the riverbed onto the tops of flat boats, with the excess water draining overboard. Under normal conditions some 100 tons are dredged daily.

Laden with coal, the capacity being from ten to twenty tons a load, the flatboats are taken to the shore from which the coal is conveyed to the coal piles…the beds being up to some three hundred feet in length and as wide as 150 feet. Some six or eight weeks are spent in dredging the larger coal and latter the dredges go over the same places in taking in the finer…The yearly output of some forty thousand tons and giving employment to upwards of forty people in this immediate section (Bloomsburg)… Dredgers in this section are Fred Fox, Bloomsburg Dredging Company, at Bloomsburg; Luther Hess, Gulliver Brothers and Leo Hoffman, of Espy, and the Sneidman Brothers of Almedia.”

In the Danville area some of the dredgers were: “Red” Bill Prentiss and the Sudol family. Bernie Sudol purchased his equipment from Flanders Keller who had operated near Port Trevorton. Between 1945 and 1950 Keller had been selling at least 60,000 tons each year to PPL’s Sunbury electrical generation plant.2 Other large users of river coal included the American Car and Foundary Company at Berwick, The Bloomsburg Steam Heating Company, the Steelton plant of Bethlehem Steel, and PPL’s power generator at Holtwood.2 PPL also operated its own dredging operation on Lake Aldred above the Holtwood Hydroelectric Station Dam called the Manor Coal Plant. It included a dredging operation and a coal cleaning plant. Cleaned river coal was loaded on rail cars which were transported downriver on the Pennsylvania Railroad to the coal fired boilers at the Holtwood Steam Electric Station adjacent to the hydroelectric powerhouse. Manor Coal remained economically viable until 1972 when the extreme floodwaters rearranged the coal deposits in the river. The original Holtwood boilers were stokers- a pulverized coal fired boiler was added in 1955. 7

Beginning in the 1950’s environmental regulations, meant to protect the river ecosystem, drove the coal dredgers out of business. Mining operations upstream were no longer allowed to dump waste coal (which often contained usable coal) into the streams. To the best of my knowledge, Mr. Sudol was the last to operate. I last witnessed his dredge in the river, near the mouth of Kipps Run, in 1996. As far as I know, no one has dredged the river since then. Several people have told me that Bucknell University, Lewisburg PA, used Sudol’s river coal and mixed it with bituminous coal at the steam generation plant. In 1995/1996 Bucknell switched to natural gas. This unique part of American history covered a century and influenced the lives of thousands of local people.

Bill Prentiss dredging coal near Chulasky just south of Danville (Bald Top Mountain is in the back ground). Photo on page one is likely from same location and date. Photo source: Sis Hause

1 Popular Science Magazine December 1921 Volume 99 No. 6

2 Down the Susquehanna to the Chesapeake By John H. Brubaker

3 Engineering & contracting, Volume 63, Issues 5-6 By Halbert Powers Gillette June 19, 1918.

4 Jim Charles. Isle of Que River Guide, Selisngrove PA.

5 History and biological annuals of Columbia and Montour Counties. Page 27

6 Bob Bickel. “Pennsylvania River Coal” http://pennsylvaniarivercoal.net/index.html

7 Rob Black Former PPL employee